Category filter

Configure Base Print Settings for Zebra Printers

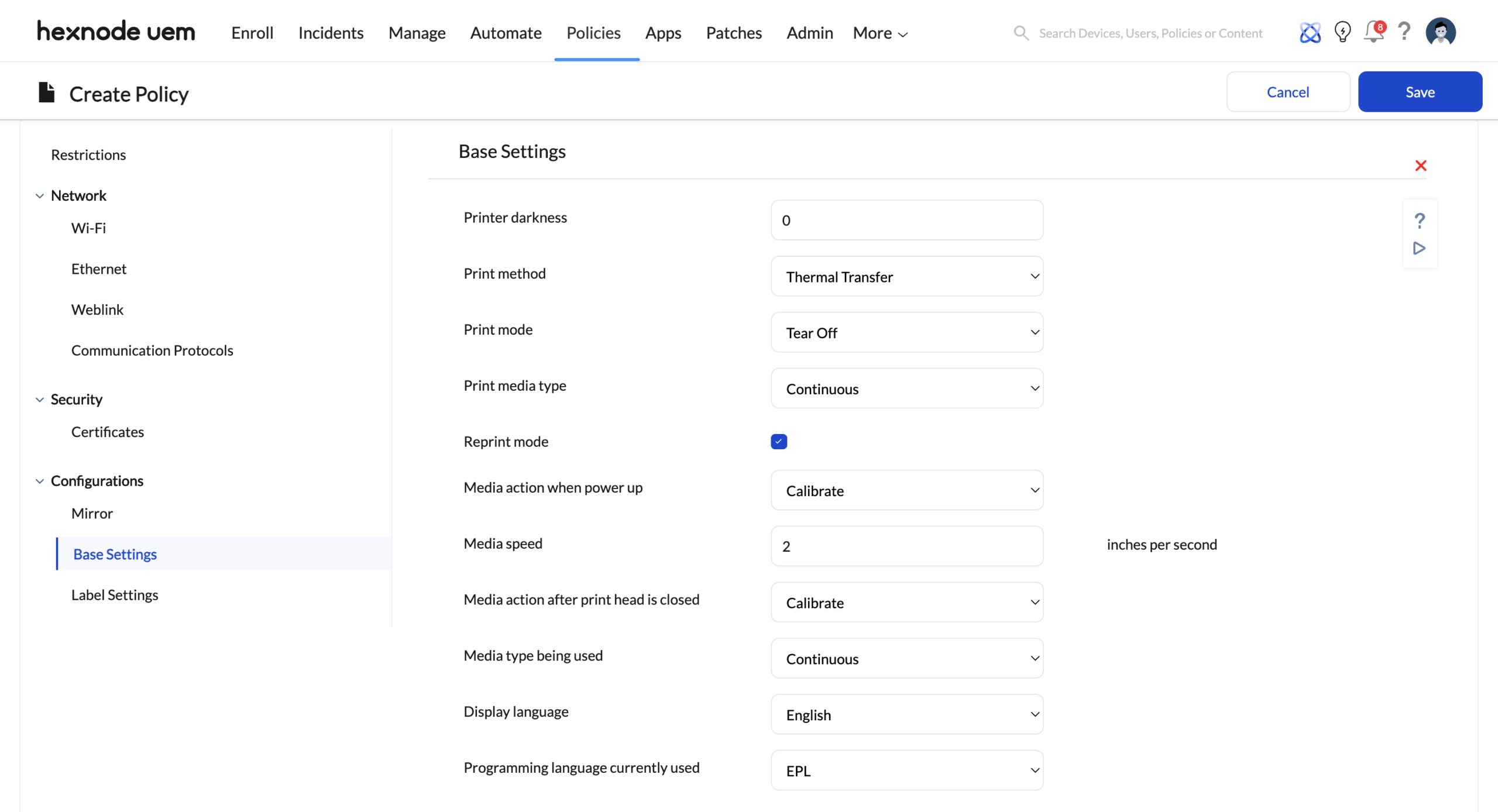

Base Settings allow you to configure the core print settings of a Zebra printer. They determine how the printer detects each label, applies heat, moves the label roll forward, positions the label for printing, and behaves when the printhead is opened or the device powers on. These settings help keep printing consistent and reliable across different types of labels and workloads.

Print settings are important because printing needs can vary depending on the environment. Labels may need to be dark enough for quick barcode scanning, printed in the correct position for packaging or product labeling, or produced quickly during high-volume tasks such as shipping or inventory processing. Adjusting these settings ensures the printer performs correctly and delivers clear, accurate results for your workflow.

How to configure base print settings for Zebra printers?

To configure base print settings:

- Log in to the Hexnode UEM portal.

- Go to Policies > Device Policies > New Policy.

- Select New Policy, or continue with an existing template if that works better.

- Choose Zebra Printers > Next > Enterprise and proceed through the next step by selecting Next again.

- Add a name and an optional description for the policy.

- Then, go to Base Settings under Configuration and click Configure.

- Thermal Transfer uses a ribbon to transfer ink onto the label, producing prints that are more durable and long-lasting.

- Direct Transfer uses heat-sensitive labels and does not require a ribbon. It is suited for short-term labels that may fade over time.

- Tear off: Positions the label at the tear bar for manual removal.

- Peel off: Feeds the label forward after printing and pauses further printing until the label is removed.

- Rewind: Rewinds printed labels onto an internal spindle for later use.

- Applicator: Works with an external applicator that applies labels automatically.

- Cutter: Cuts each label after printing.

- Delayed cut: Cuts labels after a batch has finished printing.

- Linerless peel: Feeds the linerless label forward and pauses printing until the label is removed.

- Linerless rewind: Rewinds printed linerless labels onto a spindle.

- Linerless tear: Positions the linerless label over the tear bar and continues printing without waiting for the label to be torn.

- Continuous: Uses a continuous form of media without gaps or marks.

- Auto Detect: Detects the loaded media type automatically.

- Calibrate (Default): Runs a full media calibration. The printer measures the label length and adjusts sensors. Use this when label types or sizes change to ensure accurate detection.

- Feed: Feeds the media to the next label position without recalibrating. Use this only when the printer is already calibrated for the current labels.

- Length: Measures the distance between the current gap/mark and the next one to determine label length. Useful when using similar media types that vary slightly in length. Requires the printer to be calibrated beforehand.

- No Motion: Does not move the media on startup. Use this when the label is already correctly positioned and calibration has been done earlier. Misalignment may occur if the label isn’t placed properly.

- Short Cal: Performs a quick calibration without adjusting detailed sensor settings.

- Calibrate (Default)

- Feed

- Length

- No Motion

- Short Cal

- Continuous: Uses a continuous form of media without gaps or marks.

- Gap/Notch: Uses labels separated by small gaps or cut-out notches for detection.

- Mark: Uses media with a black mark on the underside for label alignment.

- English

- Spanish

- French

- German

- Norwegian

- Portuguese

- Swedish

- Danish

- Dutch

- Finnish

- Japanese

- Korean

- Simple Chinese

- Traditional Chinese

- Russian

- Polish

- Czech

- Romanian

- ZPL (Zebra Programming Language)

- EPL (Eltron Programming Language)

- EPL_ZPL

- Hybrid XML ZPL

- Click on Save.

| Print settings | Description |

|---|---|

| Printer darkness | Controls the heat applied by the printhead while printing. A higher value results in darker output, but excessive darkness may cause barcodes to blur or reduce printhead life. Set a value that produces a clear and readable print without excessive heat. Values can be set between 0 and 30. |

| Print method |

Sets the printing method used by the Zebra printer.

|

| Print mode |

Sets how the printer handles labels after printing.

|

| Print media type |

Sets the type of label material used for printing. Selecting the correct media type ensures proper label detection and positioning. |

| Reprint mode | Enables the ability to reprint the most recent label through the Down Arrow on the printer’s control panel. |

| Media action when power up | Sets how the printer handles the loaded media when it is powered on.

|

| Media speed | Sets the printing speed in inches per second (ips). Higher speeds print labels faster but may reduce print quality depending on the label type. Supported values range from 2 to 12 ips. |

| Media action after printhead is closed |

Sets how the printer handles the media after the printhead is opened for loading and then closed again. The options here mirror those listed under Media action when power up, with the same behaviour and outcomes:

|

| Media type being used |

Sets the media type currently loaded in the printer. Choosing the correct type ensures proper label sensing and positioning during printing.

|

| Display language |

Sets the language used on the printer’s control panel. Supported options include:

|

| Programming language currently used |

Sets the printer command language the printer uses to interpret print jobs. A print job is simply the set of instructions that tells the printer what to print and how it should look. Zebra printers rely on these languages to understand how a label should appear, including the text, barcodes, graphics and overall layout, ensuring consistent results across workflows.

|

Associating the policy with target devices

If the policy has not been saved,

- Navigate to Policy Targets > Devices > + Add Devices.

- Choose the target devices and click OK.

- Click Save.

You can also associate the policy with device groups, users, user groups, or domains/OUs from the left pane of the Policy Targets tab.

If the policy has been saved,

- Go to Policies. Choose the desired policy.

- Click on the Manage drop-down and select Associate Targets.

- Choose the target entities and click Associate.

Frequently Asked Questions (FAQ)

What are linerless labels?

Linerless labels are labels without a backing paper. The roll contains only the adhesive label, treated with a special coating so the labels do not stick to each other. This increases the number of labels per roll and eliminates liner waste.

How do linerless peel and linerless tear print mode differ?

Linerless peel

Feeds the linerless label forward after printing and holds it at the output. A sensor detects that the label is waiting, and the printer pauses until the label is removed. This ensures that only one label is dispensed at a time and prevents the next label from printing until the previous one has been taken.

Linerless tear

Moves the linerless label to the tear bar after printing. The printer does not wait for the label to be torn. The next label is printed on the next part of the roll, not on top of the exposed label. This allows continuous printing while the user tears label whenever needed.